Capacitance level meters

MHL series

- Capacitance level meter contributes to automation, saves energy, and saves manpower in various kinds of production

-

Ideal for measures liquids, corrosive liquids, powders, and granules continuously. Capacitance level meters that can be used in harsh environments.

*A 24VDC power supply in integrated has obtained CE marking.

Features, keys |Videos|Adjustment function|Usage, use examples|Standard specifications

Features, keys

- High precision

Thanks to the latest circuit, the unit offers high precision and high resolution and can measure a miniature change of the level.

A circuit is employed to correct liquid adhesion to the electrode. - Can operate in harsh environments

This meter can measure stably in harsh environments with high temperatures and pressures.

The sanitary specification model has a fluorine resin coating on the electrode and so it holds up to heavy washing and is corrosion-proof. - Simple to adjust

It is easy to make the initial adjustments and span adjustment, using pushbuttons.

You can adjust response speed using the delay setting function. - Free-range power supply system is employed

The switches can be used in any location in the world and can handle power from 20 to 250 volts, AC or DC. - Obtained CE marking

A 24VDC power supply in integrated has obtained CE marking. * Please specify if you are looking for a CE compliant product.

Videos

1. This video demonstrates the actual measurement of a material interface.2. The video demonstrates the actual measurement of powder.

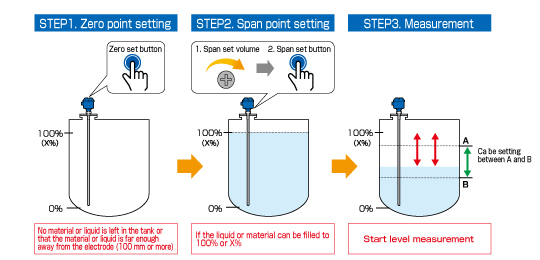

Adjustment function

This unit eliminates the inconvenience of making initial settings that is necessary with ordinary models.

You can simply set the initial settings using one-touch pushbuttons.

Usages, use examples

- Measure liquid level, powder and granular material level in various tanks. Measure material interface of liquids.

- Conductive or insulating liquids, insulating liquids with a small dielectric constant, and semi-conductive liquids.

Ex.: Various oil, various chemical solutions (acids, alkalis), various washing liquids, tap water, pure water, distilled water, alcohol, etc. - Small unit tanks, middle-sized tanks, underground pits, etc.

- Food and pharmaceutical tanks, boilers, high temperature and high-pressure tanks, various chemical-agent tanks.

Standard specifications

Amplifier

| Input power source | 20 to 250 V AC/DC |

|---|---|

| Power consumption | 24V DC:1.5W, 100V AC:2.5VA ,200V AC:3.5VA |

| Ambient operating temperature | -25℃〜+60℃ |

| Current output | Current output 4 to 20mA/DC (load resistance 500Ω or less) |

| Measurement accuracy |

±1% |

| Response speed (delay) | Variable between 0.03 to 30 sec. |

| Protection level | IP68 (integral amplifier type) / IP20(separate amplifier type) |

| Paint color | Dark blue equivalent to Munsell 5PB3/8 (integral amplifier type) Semi gloss, Munsell N3.0 (separate amplifier type) |

| Options | RS-485 Communications / Hand-held monitor |

Sensor

| Connection | Screw-in; R3/4 (can be altered to another material on request) Flange: JIS5K25AFF (can be altered to another material on request) |

|---|---|

| Materials | Surface: PFA (can be altered to another material on request) Interior SUS316L (can be altered to another material on request) |

| Allowable temperature | -10 to +150 degrees (high temperature type is also available) |

| Allowable pressure | 2MPa (normal temperatures) |