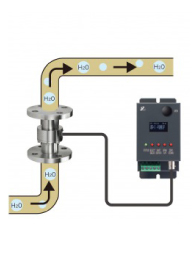

Moisture meter (in oil)

- Moisture meter in oil that can be used onlineCompact moisture meter with temperature compensation and contact output

-

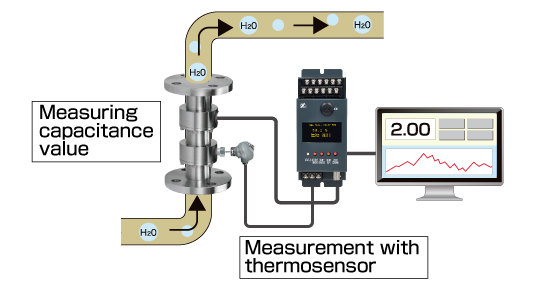

By using the difference in permittivity between oil and water and measuring the change in capacitance, the water content in the oil is detected. Depending on the oil, the dielectric constant (capacitance) may change when the temperature changes, making it impossible to measure the moisture content correctly. This product can perform temperature correction even if the temperature changes.

*Heavy oil, turbine oil for power plants, lubricating oil for hydraulic equipment, rolling oil for steelworks, etc.We have a lineup of CGL-W type dedicated to level measurement and WGL-W type compatible with moisture meters and analyzers.

Features, keys

- Achieves ultra-high sensitivity and high accuracy even in a small

size

In combination with pipeline electrodes, high accuracy (±0.1wt%) has been achieved in measuring moisture levels in oil. The separation amplifier is also ultra-compact, making it easy to incorporate into small equipment.

- Displaying measured values in real time with a display

The display is mounted on a separating amplifier.The current measured value (% display) and capacitance value (pF display) are displayed in real time.

- Simple initial setting

It is easy to make the zero and span setting, using pushbuttons. - BNC connecter make it easy to connect and disconnect the sensor and cable

Reduces connection mistakes between the sensor electrode cable and the separating amplifier. - 4 contact output settings

4 contact outputs are possible: HH, H, L, LL. Any 4-point position and alarm action direction can also be changed. - Temperature input (correction) function

A temperature sensor (sold separately) can be added for temperature correction. Correct the capacitance value from the temperature sensor information.

Applications

Since the dielectric constants of oil and water are significantly different, this difference is used to measure capacitance, and the moisture value in oil is continuously measured based on changes in dielectric constant. Depending on the oil, when the temperature changes, the dielectric constant changes (and the capacitance value changes accordingly), making it impossible to accurately measure the moisture content. For this reason, by measuring the temperature with a temperature sensor, the capacitance value is corrected according to the temperature change so that it shows a constant capacitance value even if the temperature changes. Connect to a Windows computer and perform temperature correction using dedicated software.

Standard specifications

Amplifier

| Input power source | 24V DC +-10% | |

|---|---|---|

| Power consumption | 1.5W or less | |

| Ambient operating temperature | -10℃〜+50℃ (without condensation) | |

| Current output | Current output 4 to 20mA/DC (load resistance 500Ω or less) | |

| Contact output | 4 points (operation direction changeable) + 1 point (abnormality alarm) 1a contact DC: 350V, AC: 200V (50mA) | |

| Capacitance | Measurement accurancy | ±0.1wt *1*2 |

| Temperature measurement | Measurement range | -200.0℃ to 200.0℃ *3 |

| Measurement accurancy | ±4.0℃ | |

| Response speed | Within 2 seconds (90% arrival time) | |

| Paint color | Semi gloss, Munsell N3.0 | |

| Protection level | IP20 | |

| Installation | M4 screws 2 pcs (mounting pitch 136mm) *4 | |

| Dedicated cable length | Maximum 10m | |

*1 The overall accuracy of the device may be outside this range depending on the electrode specifications and specification conditions. *2 Sample measurement is required in advance. *3 Depends on the allowable temperature of the sensor part. *4 DIN rail support is available as an option.

Sensor

| Materials | SUS304 (can be altered to another material on request) |

|---|---|

| Connection | R1/4 (can be altered to another material on request) |

| Allowable temperature | -10 to +80 degrees (without condensation) |

| Allowable pressure | 2MPa (seal part) (connection part depends on each standard) |

* Sensor part can be customized.

Temperature sensor (sheathed resistance thermometer)

| RTD | Pt100 |

|---|

* Please contact our sales department for other special specifications you may need.