- Capacitance type level switch YAL/YAE

• Can detect bubbles and deflect a level ignoring bubbles

• High performance, compact, with the latest circuitry - Capacitance type level meter MXL

Capacitance type level meter MHL

Capacitance type level meter MAE (Explosion proof)

• Can measure bubbles continuously, stably, and with a high degree of sensitivity

• Compatible with a wide range of power specifications and provides high immunity to noise

Special applications (sensing using capacitance)

This page introduces various sensing equipment using the high precision capacitance technologies. We cope with difficult applications that have been difficult to measure with conventional sensors. If you are saying, We need a level sensor that can measure in our specific conditions, then count on us. We can provide devices that will meet any need, including the following.

Continuous measuring of bubbles |Level meter of glass gauge without contact | Powder level meter in pressed supply mechanism

Compact capacitance level meter |Other applications

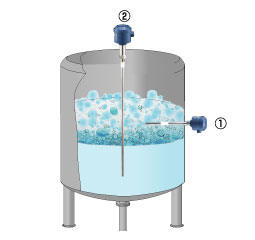

Continuous measurement of bubbles

We install high-sensitivity capacitance level meters to measure the thickness of the bubble layer that is caused by chemical reactions in a production line. The level meter can measure the bubble level continuously, not just from time to time.

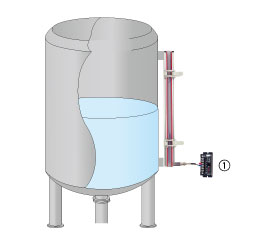

Measures the level in a glass gauge

Sensors already existed that could measure liquid levels in insulated glass tubes at a specified time. Our innovation is a level sensor that can measure liquid levels continuously, without contact.

- Continuous level meter for glass gauge MHL-R1

• Can measure the liquid level continuously with completely non contact

• After the sensor is installed, you can check the liquid level by looking through the glass tube

• There is no need to insert a float or other element into the glass tube

(Application)

• Non-contact level measurement of liquid in a glass tube, test tube, or small vessel

• Non-contact liquid level measurement in a Teflon and plastic tube

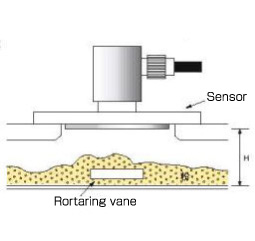

Measure the powder level in a pressed powder supply mechanism

This level meter can measure the level of powder in a sealed container in harsh conditions involving a lot of flying powder and dust. See the example case below.

- Capacitance level meter (special type)

We managed to control the powder level using a capacitance level meter on the machine that dispensed the powder into a table type sealed container.

We solved this problem by design and produced special flat electrode as shown in figure 2, and measured change of capacitance without contact material.

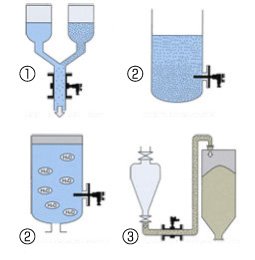

Compact capacitance level meters

Use this level meter to measure continuously the liquid level in a small tank or in a limited space. This level meter is compact, easy to wash, and can be used in harsh environments. Below describes an application example.

- Cleaning liquids, chemical liquids in semiconductor manufacturing systems

Measure levels of cleaning liquids, liquid chemicals, and pure water, and improve the yield rates. - Measure a level of liquefied gas

Measure levels of liquefied gases (liquefied nitrogen, natural gas LNG) in low temperature environments. - Measures levels of oil and engine oil

Continuously measure levels of lubrication oil in systems and equipment, and engine oil.

Other applications

We do not use just the standard amplifiers. We can provide a variety of capacitance sensor amplifiers, including highly sensitive ones, to meet various requirements. We have devices to deal with the following applications, beyond the simple measurement of material levels.

- Measure mixed ratio of two liquids

• Measure mixed ratio of two different liquids

• To measure the ratio in a mixture, the dielectric constant of the two liquids must be different - Measure liquid density, water content in liquid

• Measure liquid density

• Measure the water content of a liquid - Measure density of powder and grains in a pipe

• Measure the powder and granule density in a pipe

• The liquid density may not be measured appropriately, in some conditions

- This product is good choice in the following conditions

-

• Normal liquids, powder, grains, fine powder, lumps ? Standard applications

• Small units, small tanks, small vessels, plumbings ? Applications for small tanks

• High temperature, high pressure, vacuum, low temperature ? High temperature, high pressure applications

• Sanitary, foods, phermaceuticals ? Sanitary, foods, pharmaceutical applications

• Non contact measurement, analyze liquid ? Report the capacitance